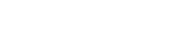

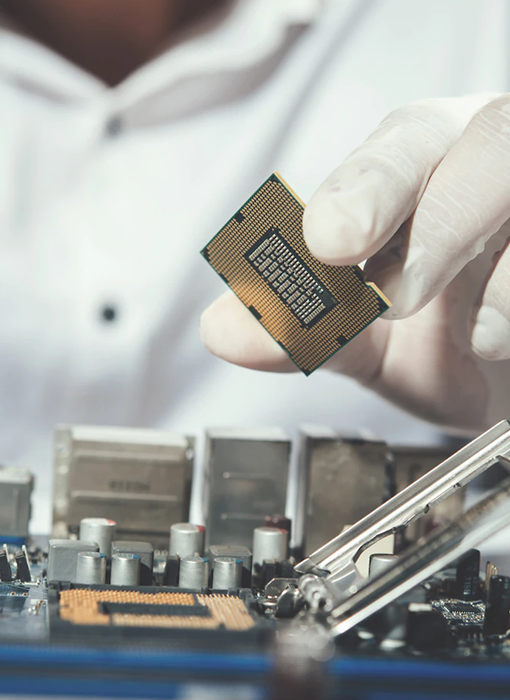

CNC

CNC engraving machine: suitable for cutting electroplated products, PMMA, hardened PC and aluminum parts

CNC machining accuracy: < 200mm size ± 0.05mm, 200-400mm size ± 0.1mm

CNC engraving and stamping process comparison:

① The flatness of the product edge: CNC > stamping, there is burr at the cutting edge of the stamping part, which is not very smooth and flat, and there will be a horizontal and vertical line like indentation at the cutting edge; CNC products, such as stainless steel and aluminum parts, have bright and neat traces of knife path on the surface

② Adaptability of product forming: CNC > punching, punching can only cut materials with certain willfulness, such as PC, aluminum, stainless steel, etc., but cannot cut surface hardened materials, such as hardened PC, PMMA, plating, etc

③ Capacity: blanking >> CNC. In terms of product forming capacity, blanking is far greater than CNC. At the same time, blanking can be performed with adhesive backing; CNC can not be molded with glue, and it needs a single piece of glue

④ Die cost: punching >> CNC, the cost of hardware die used for punching is higher, generally forming at 3-5K, and the cost of special processes such as embossing and bending is higher; CNC tool cost is about 100

READ MORE ?